Hot Forging Electric Screw forging Press better than friction forging press

Price 300000 USD ($)/ Set

Hot Forging Electric Screw forging Press better than friction forging press Specification

- Hardness

- Up to 65 HRC (core components)

- Surface Treatment

- Polished and anti-corrosion coated

- Process

- Hot Electric Screw Forging

- Product Type

- Forged Equipment

- Material

- Steel

- Technology

- Forging

- Application

- Hot forging high-strength parts in automotive, aerospace, and machinery industries

- Dimension (L*W*H)

- 3200mm 1950mm 4200mm (customizable)

- Weight

- Approx. 25 Ton

- Color

- Green

- Ram Speed

- 30-60 strokes/min

- Power Supply

- 380-415V, 50/60Hz, 3 Phase

- Precision

- High repeatability, ±0.1 mm tolerance

- Cooling System

- Integrated cooling for extended operation

- Energy Efficiency

- 30% higher compared to friction screw press

- Max Stroke

- 400 mm

- Control System

- PLC with Touch Panel HMI

- Noise Level

- Less than 78 dB(A)

- Rated Capacity

- 1600-6300 kN (customizable)

- Driving Method

- Electric Servo Direct Drive

- Safety Features

- Enclosed guarding, emergency stop, overload protection

Hot Forging Electric Screw forging Press better than friction forging press Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Shanghai Port, Qingdao Port

- Payment Terms

- Cash on Delivery (COD), Days after Acceptance (DA), Delivery Point (DP), Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Western Union, Paypal, Cash Against Delivery (CAD), Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 5 Sets Per Month

- Delivery Time

- 60 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- WOODEN CASES

- Main Export Market(s)

- Australia, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia, Central America

- Main Domestic Market

- All India

- Certifications

- CE ISO

About Hot Forging Electric Screw forging Press better than friction forging press

Electric screw press is a forging machine with many applications, having the dual nature of press and forging hammer. Structure is simple, small volume, short drive system, operation is convenient, running is safe and low maintenance. Electric screw press is suitable for all kinds of precision forging, finishing, coining ,embossing and leveling etc process.The strike energy can be set accurately according to the die precision, can reduce the time of mechanical stress and the amount off time the hot work piece is in contact with the die, thus prolonging the die life.The frame is rigid, good guide ability, strong bias load resisting ability, can be used in multi-die forging, it is a energy-saving and environmental protection forging press.

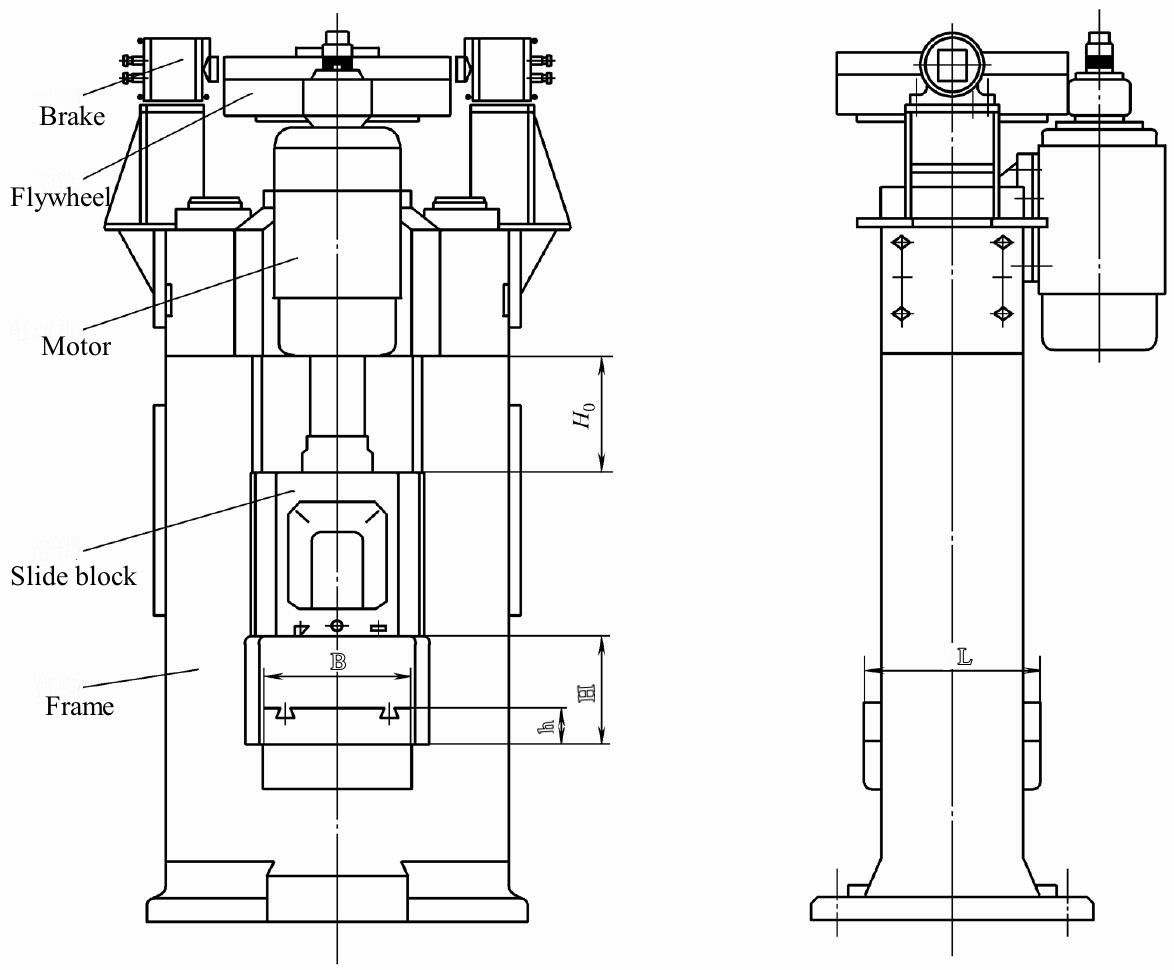

Electric screw press working principle

Slide moves up & down driven by motor through pinion, gearwheel and screw, gearwheel has enough inertia act as flywheel. After input start signal, motor from stationary state drives slide accelerate downwards through pinion and gearwheel, motor stop accelerating after reaching required speed by pre-set blow energy, Kinetic energy stored by gearwheel works, e.g. forming work. At the same time, motor immediately drives gearwheel to reversal rotation, when reaches a certain point, motor will start to brake, drives slide back to pre-set position. Since brake is by motor when slide is in return stroke, mechanical brake only works when slide is close to up dead point, brake material is not easy to wear, no need frequent change.

Futures of screw press

- Using AC frequency conversion direct torque control technology servo driving system , frequency converter is ABB brand, with advanced technology.

- The striking energy is precisely setting with high deforming precision, suitable for various nonferrous metal precision forging operation.

- Easy programming for automation.

- Bottom point is not fixed, not necessary to adjust the die height, without forging dies stick together phenomenon.

- Due to the striking energy precise control, the forging die life is elongated greatly.

- The main frame structure is simple, easy operating and maintenance.

- The moving parts with low noise, low vibration, satisfy environmental protection, and reduce the foundation building costs.

- Relatively short stroke, the energy output is stable, and repeatability precision is high .

Advantages of Anyang screw press design

Our electric screw press adopts gear drive mode, features of this drive mode are: adopts special motor, high RPM, less torque, different tonnage press with different power special motor, easy to replace when motor breaks down, easy & simple maintenance, motor performance is not affected when screw guide bushing is worn out., efficiency of electric screw press improved a lot with continuous improvements & innovations in many years, this gradually established our leading position in electric screw press market.

Screw structure:Screw is CrMoV high alloy forging, thread type has good fatigue resistance, no self-lock, stable installation, short screw, increased press rigidity.

Nut:Made of bronze material, installed inside slide, has good abrasive resistance and emergency sliding performance.

Slide Block:The slide block is using high class steel casting with full aging treatment to relief stress.

Guiding system:The guiding system has 45 degree arrangement with the slide block surface, to keep constant clearance and not affected by the thermal expansion. The guiding set is using bronze and steel. The guide rail with nitrogen treatment, the guide plate can be adjusted from each direction to ensure the smallest guide rail clearance. The slide block guiding length and rigidity etc. can ensure to produce the high quality products with long die life.

Brake apparatus:The brake directly effected with gear make it braking at any position, the brake is closed through spring force, and opening is pneumaticly controlled.

Driving unit:The precision screw drive is driven by squirrel-cage three phase positive and reverse asynchronous motor, this kind of driving unit with low maintenance and high reliability features.

Lubricating oil circulation:There is a monitoring lubricating oil circulating system to lubricate the spiral thrust bearing constantly. The guide rail lubricating features will sustain in numbers of circulation.

Combined type press frame:There are numbers of advantages of the combined type frame, to eliminate the notch stress centralization between the working table and columns, between the crossbeam and columns. The large size of forging press can be dismantled and transported by several pieces. The frame adopts pre-stressed connection with high rigidity, under same tensile stress, the extensibility is only 20% of the unibody designed frame.

Automation electric screw press forging line

The electric screw press as the key equipment, Anyang forging press company can supply the forging production line for the customers, include cutting equipment, heating equipment, preform forging equipment, forging robots, Trimming equipment and integrated system etc.

Forgings forged on screw press

Electric screw press can forge Claw Pole, connecting rod, form machinery, spherical hinge, Auto parts forging, control arm, riggings etc precise closed die forgings.

Advanced Electric Servo Direct Drive

Experience the advantages of electric servo direct drive technology, delivering consistent force and precise control with every stroke. The system enables high-speed operationup to 60 strokes per minutewhile reducing energy consumption and noise, resulting in lower operating costs and a safer factory environment.

Precision and Quality Assured

Achieve exceptional accuracy with a high repeatability tolerance of 0.1 mm. The robust steel frame, advanced surface finishing, and hardened core components (up to 65 HRC) guarantee long-term reliability and minimal wear, ensuring consistent quality in each forged part.

Integrated Safety and User-Friendly Operation

Operator safety is paramount with enclosed guarding, emergency stop features, and overload protection. The integrated PLC control and touch panel HMI allow straightforward operation, monitoring, and quick customization to the forging process requirements. Enhanced cooling extends operational periods, making it ideal for industrial-scale production.

FAQs of Hot Forging Electric Screw forging Press better than friction forging press:

Q: How does the electric screw forging press improve energy efficiency compared to friction forging presses?

A: The electric servo direct drive system in this press reduces energy losses associated with mechanical friction, resulting in up to 30% higher energy efficiency compared to traditional friction screw presses. This leads to lower electricity consumption and operational costs.Q: What types of applications is this electric screw forging press suitable for?

A: This press is ideal for hot forging of high-strength parts in sectors such as automotive, aerospace, and heavy machinery. It accommodates demanding industrial environments that require high precision and the ability to customize capacity and stroke.Q: When is the optimal time to use an electric screw forging press in the production process?

A: This press is best utilized during the hot forging stage, where precise force, repeatability, and energy efficiency are crucial for forming parts that require high mechanical strength and close dimensional tolerances.Q: Where can this forging press be installed and operated?

A: The press can be installed in industrial facilities worldwide, operating efficiently on power supplies of 380415V, 50/60Hz, 3-phase. Its design and construction adhere to the requirements of global distributors, manufacturers, exporters, suppliers, and traders.Q: What are the main benefits of using this hot forging electric screw press over conventional models?

A: Key benefits include higher energy efficiency, enhanced precision and repeatability, significantly lower noise levels, improved safety features, extended operational cycles due to integrated cooling, and ease of use via a PLC touch panel HMI.Q: How is the forging process controlled and monitored on this press?

A: An advanced PLC system paired with a touch panel HMI allows operators to precisely control, monitor, and adjust forging parameters in real time, ensuring process reliability and easy troubleshooting.Q: What safety measures are incorporated into the design of this forging press?

A: Safety is ensured with enclosed guarding, emergency stop functionality, and overload protection, minimizing risks during operation and maintaining a safe working environment for operators.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Close Die Forging Machine Category

Electric Screw Press Machinery Anyang Forging Hammer

Price 260000 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Steel

Color : Blue & Gray

Application : Other, Press Forging, Coining, Precision Forming

Technology : Forging

31.5KJ CNC forging hammer for track link drop forging hammer india

Price 445238 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Carbon Steel

Color : customized

Application : Auto Parts

Technology : Forging

New direct driving screw forging press electric direct driving forging press

Price 260000 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Carbon Steel

Color : Customized color forging press

Application : Auto Parts

Technology : Forging

Electric Screw Forge Press for Convenient Operation

Price 260000 USD ($) / Set

Minimum Order Quantity : 1 Set

Material : Steel

Color : Blue & Gray

Technology : Forging

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry